Selecting an appropriate location for a driver safety zone location requires careful consideration of various factors to ensure the safety of all users of the area. Driver safety zones are designed to ensure that the driver of the vehicle being unloaded or loaded is safety from injury or incident from mobile plant and equipment and other vehicles.

Some of the items to consider when selecting a driver safety zone are as follows:

- Access. Access to the driver safety zone by the delivery drivers should be via a marked and barricaded walkway wherever possible. Walkway layouts should be away from mobile plant and forklifts.

- Visibility. The driver safety zone should be in an area where the truck driver should be able to see their truck or vehicle being loaded, especially for CoR purposes. The driver safety zone should also be in an area where forklift drivers and see anyone in the area and ensure they are safety.

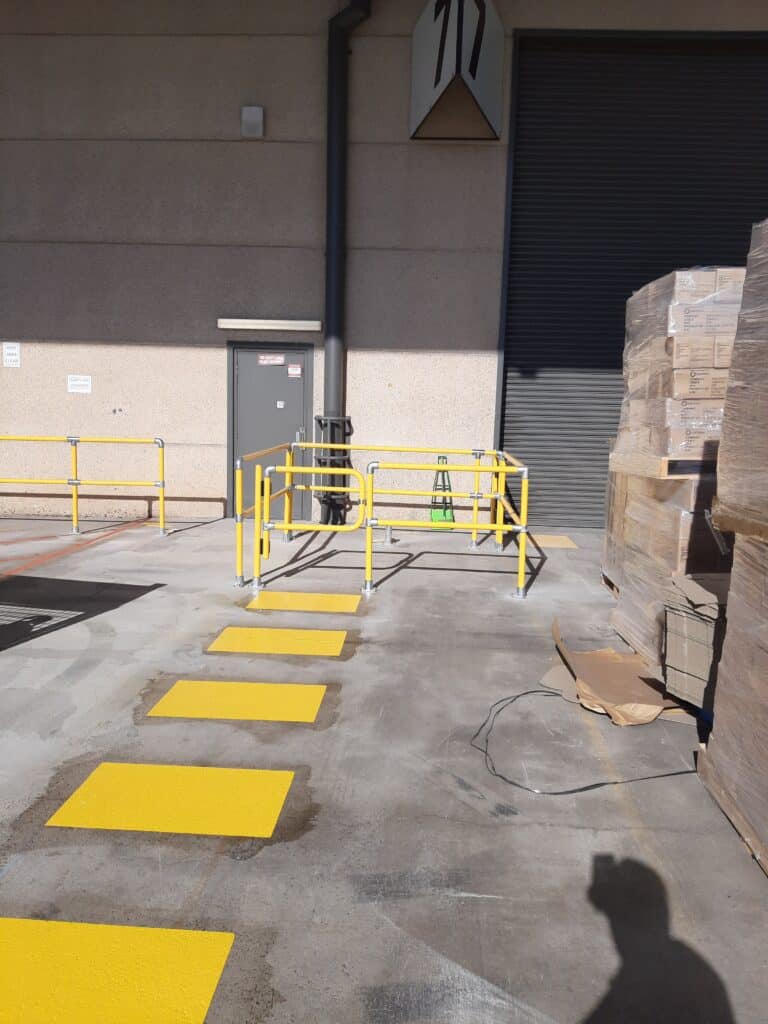

- Barriers. The driver safety zone should be protected by barriers suitable for protection from the plant, forklifts and vehicles in the area. The barriers should have self-closing gates at the access points into and out of the zone. Barriers should also be suitable for the operating environment and made from a material that is long lasting. This may include the D-flexx barrier system which will not bent and leave sharp edges if broken. The D-flexx system is an impact rated system that won’t rust or deteriorate in the weather, making it the perfect barrier system for a driver safety zone.

- Weather. The driver safety zone should be in an area that is protected from the weather. This includes the heat of the day and also during wet weather.

- Surface. The surface of the driver safety zone should be a smooth level surface that will prevent slips, trips and falls.

- Signage. The driver safety zone should have clear signage displayed to designate the area.

- Key Board. Some driver safety zones have a Key Board installed for the truck driver to hang their keys on. This allows the forklift operator to see where the keys for the delivery vehicle are located. This will also stop accidental starting of the vehicle during loading or unloading.

- Amenities. The driver safety zone should be located in such a way that there is clear access to amenities for the drivers to use. This can include via a marked walkway or with amenities installed within the designated area. Some amenities include, Toilet access, washroom facilities, Coffee machine or refreshment/eating areas.

- Emergency planning. The driver safety zone should be located near commonly used walkways for easy access to the emergency assembly area. It is critical that all workplace traffic management controls work hand in hand with emergency response procedures and the emergency management plan.

- Number of drivers. The driver safety zone should be able to accommodate the number of delivery drivers that use the area. This may need to be large enough to accommodate social distancing.

- Surrounding hazard. The driver safety zone should be located in an area where surrounding hazards don’t put those in the driver safety zone at risk of harm. This may include ensuring that there is no racking behind the zone that may pose a risk of stock dropping into the zone.

- Training. The staff in the workplace need to be trained in the use of the driver safety zone including who should use the area. All delivery drivers should cover off on the driver safety zone use and requirements when they complete the site specific safety induction. Most deliver drivers to the site would be regular drivers, to some extent, so this will help with them all completing a site specific safety induction.

These are the minimum requirements for a driver safety zone location and should be implemented with a thorough risk assessment has been completed of the area. For assistance with your workplace traffic management driver safety zone or consulting, reach out to our team today.